Marbre and granite are more than just materials—they’re timeless symbols of elegance, durability, and artistry. At Sarhan for Marble & Granite, we’ve perfected the process of transforming raw Egyptian stone into world-class products, blending craftsmanship, cutting-edge technology, and sustainability. Since 1996, our commitment to quality has made us a trusted partner for wholesalers, retailers, distributors, architects, designers, and construction professionals worldwide.

In this article, we’ll take you through our meticulous production process, highlight the skill of our artisans, and showcase how sustainability and international standards shape every product we create.

From Quarry to Masterpiece: The Sarhan Production Process

The journey from raw stone to premium marble and granite is a multi-step process requiring precision, expertise, and dedication. Here’s how Sarhan ensures excellence at every stage!

Step 1: Quarrying

Our story begins in Egypt’s renowned quarries, where some of the world’s finest marble and granite originate. Sustainability is a core value at Sarhan, and we encourage our quarrying-partners to be environmentally responsible with their methods to minimize waste and reduce environmental impact.

- Stone Selection: We carefully choose blocks of Sinai Pearl, Galala Classic, Sunny Nour, and other iconic Egyptian stones for their unique veining, durability, and aesthetic appeal.

- Technology and Safety: Modern machinery and rigorous safety protocols ensure precise extraction while protecting both workers and the environment.

Step 2: Block Transport and Preparation

The extracted stone blocks are transported to our factory, where they are prepared for cutting and finishing.

- Inspection: Each block undergoes a detailed quality check to ensure it meets our stringent standards.

- Sustainability in Action: Any excess material is repurposed for smaller products, minimizing waste.

Step 3: Precision Cutting

Cutting is where raw stone begins its transformation into usable slabs, tiles, or custom shapes.

- Advanced Equipment: High-tech saws cut massive blocks into precise slabs.

- Standardisation: Our team tailors the cutting process to meet majority client requirements for thickness and dimensions.

Step 4: Surface Finishing

Finishing brings out the natural beauty of the stone while preparing it for its intended application. Sarhan offers a variety of finishes:

- Polissage: A high-gloss finish that enhances the stone’s patterns and veining, ideal for interiors.

- Ponçage: A matte finish for modern, understated elegance.

- Sandblasted and Bush-Hammered: Textured finishes for outdoor and non-slip surfaces.

- Tumbled, Brushed and Antique: Rustic finishes that add character to any design.

Step 5: Quality Assurance

Before any product leaves our factory, it undergoes rigorous quality checks to ensure it meets international standards.

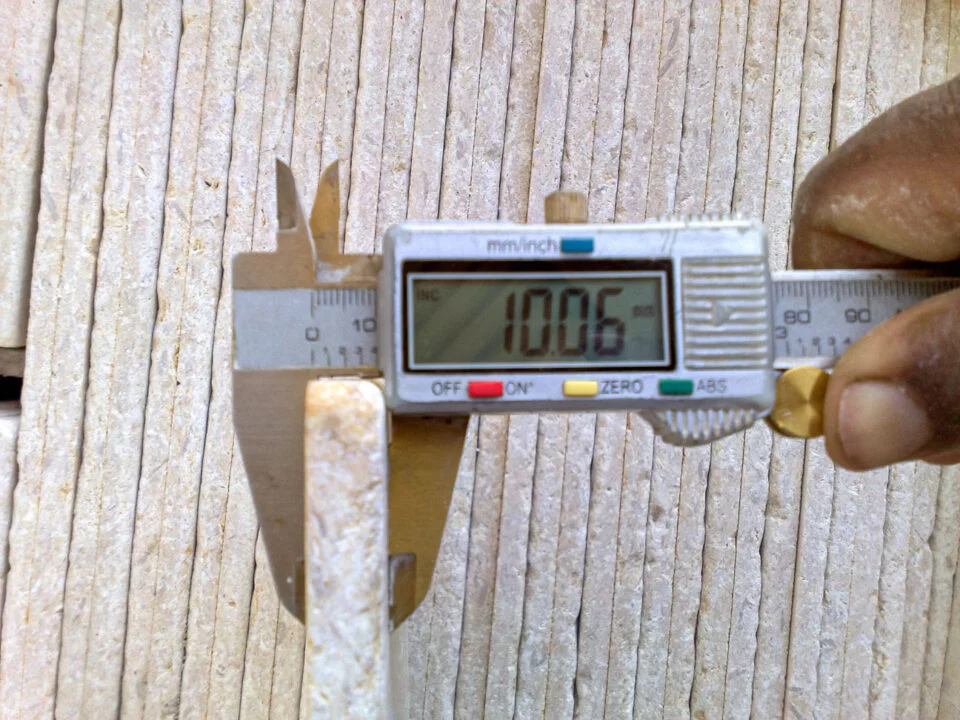

- What We Test: Uniformity, dimensions, thickness, finish consistency, and structural integrity.

- Certifications: Apart from our ISO 9001:2015 certification, our products comply with global benchmarks, ensuring they’re export-ready for markets worldwide.

Step 6: Custom Fabrication

For clients with unique needs, Sarhan specializes in creating custom products like sinks, basins, and decorative stonework. Our artisans combine traditional handcrafting techniques with modern tools to achieve stunning results.

The Human Touch: Skilled Artisans at Work

At Sarhan, our team of skilled artisans is the backbone of our operations. These craftsmen bring decades of expertise to every slab, tile, and custom piece, ensuring each product is a work of art.

- Generations of Expertise: Many of our artisans come from families with a long history in stonework, preserving and evolving traditional techniques.

- Dedication to Perfection: From polishing to intricate carvings, their attention to detail ensures every piece meets our clients’ expectations.

Sustainability: A Commitment to the Future

Sustainability is not just a practice at Sarhan—it’s a philosophy that guides every step of our production process.

- Water Recycling: Our factories are equipped with systems that recycle water used during cutting and polishing, conserving precious resources.

- Waste Minimization: Excess stone is repurposed into smaller products or used for landscaping applications, ensuring nothing goes to waste.

Why Sarhan Stands Out

When choosing marble or granite for a project, quality, craftsmanship, and reliability are paramount. Here’s what sets Sarhan apart:

1. Unmatched Quality

Every Sarhan product is crafted with precision and inspected for excellence. Our attention to detail ensures durability, beauty, and functionality in every slab.

2. Extensive Variety

From the subtle elegance of Galala Extra to the bold tones of Red Aswan granite, we offer a wide selection of stones and finishes to suit any design or application.

3. Expert Accommodation

Whether it’s bespoke basins, patterned tiles, or intricate carvings, we can tailor solutions to meet the unique needs of our clients.

4. International Standards

Sarhan products are designed to meet the demands of global markets. Our certifications and rigorous quality checks ensure every piece exceeds expectations.

Experience the Craftsmanship of Sarhan

At Sarhan for Marble & Granite, we don’t just produce stone—we craft experiences. Our products are a testament to the skill, dedication, and passion of our team, ensuring every piece reflects the beauty and heritage of Egyptian stone.

Whether you’re designing a luxurious interior or a resilient outdoor space, Sarhan has the expertise and materials to bring your vision to life.

- Discover the Sarhan difference today:

Final Thoughts

Craftsmanship, sustainability, and precision are the pillars of Sarhan for Marble & Granite. With decades of expertise and a commitment to quality, we transform raw Egyptian stone into world-class products that stand the test of time. Let us be your partner in creating timeless designs with the enduring beauty of marble and granite.

Experience Sarhan today—where artistry meets excellence.

wonderful issues altogether, you just gained a new reader.